A Con Edison district steam museum receives major upgrade with stable domestic hot water and building heat, without a quencher.

The museum in New York City relies on central steam from the Con Edison district steam loop to provide both domestic hot water and space heating for galleries, back-of-house areas, and public spaces. Reliable temperature control is critical to protect sensitive collections, maintain visitor comfort, and support building operations in all seasons. Lawrence Lowy Associates was engaged for its expertise with Maxi-Therm steam heat exchangers and steam-side control to design a packaged solution that would make use of the existing district steam while tightening temperature control and simplifying operation. The stakes included protecting high-value artifacts, avoiding temperature swings in occupied spaces, and ensuring safe, code-compliant operation of a high-pressure steam-fed system.

Project Overview: Existing System Constraints and Risks

Before the project, the museum’s steam and hot water infrastructure faced several practical and operational limits tied to its district steam supply and aging distribution equipment. The building needed to convert high-pressure steam from Con Edison into stable hot water for both domestic and space heating loads, but legacy equipment and controls made it difficult to maintain tight temperature bands during occupancy.

Key issues included:

- Limited control over incoming district steam pressure and temperature.

- Concern over temperature swings at domestic hot water fixtures during varying load conditions.

- The need to avoid quencher-based arrangements that can waste energy and complicate control.

- Operational risk around reliability and safety in a high-pressure steam environment.

These constraints created risk to comfort in galleries and public areas, as well as to back-of-house operations that depend on predictable hot water and heating. Any instability in the steam-to-water conversion process could lead to occupant complaints, increased manual intervention by operations staff, and concerns about long-term reliability of the system.

Solution: Selected Equipment and System Design Rationale

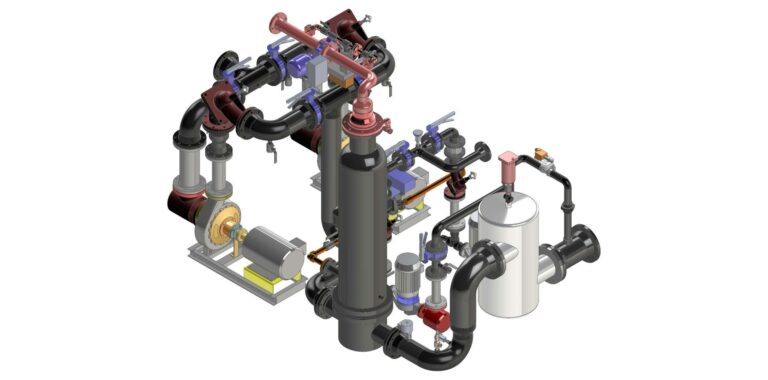

The team selected a Maxi-Therm duplex steam-to-water heat exchanger package to convert Con Edison district steam into domestic hot water and heating water for the museum’s distribution system. This configuration was chosen to provide stable control, efficient heat transfer, and a compact footprint suitable for a mechanical room in a dense urban facility.

The design rationale focused on:

- Using a duplex arrangement to provide redundancy and smoother operation across low to high load conditions.

- Leveraging Maxi-Therm’s heat exchanger design for rapid, stable response to changing steam and water-side conditions.

- Converting high-pressure district steam to controlled hot water temperatures without relying on quencher piping.

- Simplifying maintenance and inspection with packaged components and clear isolation points.

By pairing the duplex Maxi-Therm package with appropriate controls and safeties, the solution provided the museum with a predictable way to use district steam as the primary energy source while supporting both domestic hot water and space heating requirements.

Engineering Approach and Coordination

Lawrence Lowy Associates acted as a technical partner to the project team, not just an equipment supplier. The engineering approach began with a review of the museum’s steam supply conditions, domestic hot water needs, and space heating loads, as well as how those demands varied by season and occupancy.

Key elements of the approach included:

- Evaluating incoming Con Edison district steam parameters and how they interact with the museum’s distribution system.

- Reviewing domestic hot water and heating load profiles to size the duplex package for peak and part-load operation.

- Coordinating with the design engineer, installing contractor, and facility operations staff on piping arrangements, controls, and access.

- Planning for commissioning steps, including start-up sequencing and verification of control setpoints under real operating conditions.

During implementation, the team supported the contractor and facility staff with guidance on control strategy, valve selection, and recommended operating parameters so that the final installation aligned with both the design intent and day-to-day operational needs.

Results & Operational Impact: Post-Installation Performance

After installation and commissioning, the museum gained a more stable and predictable steam-to-hot-water interface for both domestic and space heating use. Operations staff can now rely on the Maxi-Therm duplex system to manage incoming district steam and deliver controlled water temperatures across a wide range of load conditions.

Observed improvements include:

- Tighter control of domestic hot water and heating water temperatures, reducing swings during occupancy.

- Reduced need for manual intervention in the mechanical room during changes in outdoor conditions or museum traffic.

- More efficient use of the Con Edison district steam supply by eliminating quencher-based arrangements.

- Increased confidence in the safety and reliability of the steam-side and water-side equipment.

These changes support a more consistent environment for visitors and staff while simplifying the daily workload for the facility and operations teams who manage the system.

Why This Matters for Similar Facilities and Applications

Museums, galleries, campuses, and institutional facilities in New York and New Jersey often rely on district steam or central boiler plants to support domestic hot water and space heating. When legacy equipment and controls cannot keep up with current demands, operators may see temperature swings, nuisance alarms, or inefficiencies that are difficult to diagnose.

Projects like this museum installation show how a purpose-built Maxi-Therm package and a thoughtful steam-side design can help similar facilities:

- Convert high-pressure steam into stable, usable hot water for multiple loads.

- Improve comfort and reliability without expanding mechanical room footprints.

- Modernize control strategies while respecting existing piping and utility constraints.

Lawrence Lowy Associates provides focused support for steam heat exchanger and control solutions in the NJ/NY region, bringing practical experience with district steam, packaged HX systems, and facility coordination.

Request a Free Specification Quote

Commercial, institutional, and campus facility teams in New York and New Jersey can request a no-obligation specification review to evaluate steam-to-hot-water solutions like this museum installation. The team will review loads, controls, safety requirements, and available mechanical space to recommend an engineered approach that makes better use of existing steam infrastructure while supporting domestic hot water and heating needs.