Introduction: Facility Profile and Project Stakes

A hospital campus in Long Island, NY added a new building that needed reliable, efficient heating tied into the existing central steam system. The facility wanted to avoid a separate, standalone boiler plant while still delivering stable hot water for space heating and critical areas. Lawrence Lowy Associates (LLA) was asked to help engineer a solution that would use campus steam as the primary energy source, manage temperatures precisely, and keep maintenance requirements reasonable for a 24/7 healthcare environment. Key stakes included temperature stability for patient care, system reliability in winter conditions, and control over long‑term operating and project costs.

Project Overview: Existing System Constraints and Risks

The hospital’s existing campus steam system was well‑established, but the new building introduced several challenges:

- The design team needed an efficient way to convert steam to hot water for building heating without building a new boiler plant.

- Temperature control had to be tight to support patient comfort and sensitive areas.

- The owner wanted to minimize additional infrastructure cost and avoid high ongoing maintenance demands.

Relying on ad‑hoc or oversized equipment would have increased project costs, complicated maintenance, and risked uneven performance across the new building. The hospital needed a packaged solution that could plug into the existing steam network while meeting modern expectations for control and efficiency.

Solution: Selected Equipment and System Design Rationale

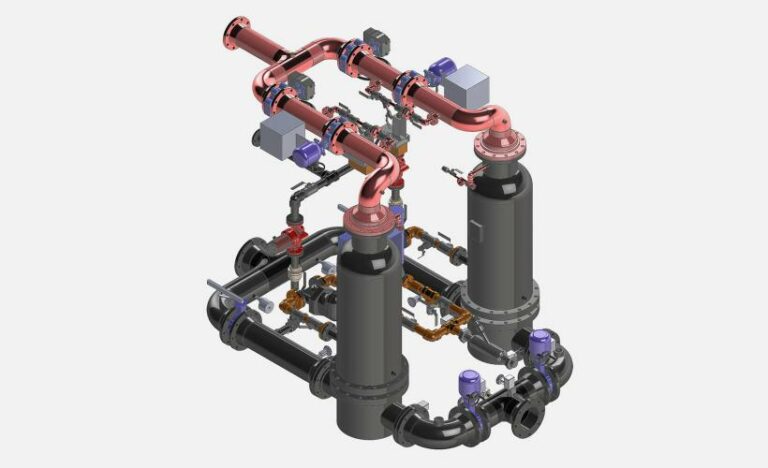

To meet these requirements, LLA recommended installing a Maxi‑Therm DMCU‑Z‑UP‑1700G‑30F‑95P package, designed to operate at 1700 GPM with a 30‑degree temperature rise. This configuration was selected because it:

- Delivers high‑capacity heat transfer from steam to hot water

- Supports the new building’s flow and temperature requirements using campus steam.

- Provides precise temperature control

- The packaged design and controls maintain a stable hot water supply, even under varying loads.

- Integrates cleanly with existing steam infrastructure

- Uses campus steam as the energy source, avoiding the need for a separate boiler plant.

- Simplifies service and ownership

- A factory‑engineered package is easier to document, inspect, and maintain than piecemeal field‑built solutions.

By centering the design on a Maxi‑Therm package, the hospital gained a purpose‑built steam‑to‑hot‑water system tuned to the building’s specific load and temperature needs.

Consultative Execution: Engineering Approach and Coordination

LLA supported the hospital and design team through the full engineering and coordination process. The team:

- Evaluated loads and integration options

- Reviewed the new building’s heating demand and how it would interact with the existing campus steam system.

- Confirmed that a 1700 GPM, 30‑degree rise Maxi‑Therm unit would cover present and near‑term needs.

- Coordinated with engineers and contractors

- Worked with the project engineer and mechanical contractor on piping, controls, and valving details.

- Ensured the steam, condensate, and hot water connections were arranged for safe, efficient operation and future service access.

- Supported commissioning and turnover

- Assisted with start‑up, tuning, and verification of temperature control and flow.

- Helped facilities staff understand operating parameters, setpoints, and routine inspection points.

This consultative approach reduced design uncertainty, kept the project aligned with hospital standards, and helped the new system slot smoothly into the existing campus infrastructure.

Results & Operational Impact: Post‑Installation Performance

With the Maxi‑Therm system in place, the new hospital building achieved a reliable and efficient heating solution backed by the campus steam network. The project delivered:

- Less maintenance compared to traditional boiler plants

- The packaged Maxi‑Therm unit requires fewer field‑built components and less day‑to‑day attention.

- Improved energy performance

- Efficient steam‑to‑hot‑water conversion and stable control reduce wasted energy and help manage utility costs.

- Lower overall project costs

- Leveraging the existing steam system avoided the expense of new boilers, flues, and associated support systems.

For facilities staff, the system is easier to monitor and service than a full standalone plant, and it supports consistent temperatures across the new building with fewer troubleshooting calls.

Why This Matters for Similar Facilities and Applications

Hospitals, campuses, and large institutional facilities across New York and New Jersey often face similar challenges when adding new buildings: they want to use existing steam infrastructure but still deliver modern, tightly controlled heating. This project shows how a Maxi‑Therm‑based solution, supported by Lawrence Lowy Associates, can:

- Turn central steam into reliable, controllable hot water for new or renovated buildings.

- Reduce project cost and complexity by avoiding separate boiler plants.

- Provide stable, maintainable equipment that fits hospital expectations for uptime and compliance.

The same approach can be adapted for other healthcare facilities, higher‑education campuses, and large institutional sites looking to expand while keeping their steam systems at the core of their energy strategy.

Request a Free Specification Quote

Lawrence Lowy Associates helps hospitals and campuses in NJ/NY design and implement steam‑to‑hot‑water solutions that improve control, efficiency, and maintainability. If you are planning a new building or major renovation and want to leverage your existing steam system, request a free specification quote to review your loads, control requirements, and integration constraints. LLA will evaluate your current infrastructure and outline a Maxi‑Therm or RTK‑based solution engineered to deliver stable temperatures, manageable maintenance, and long‑term value for your facility.